PROACTIVE: Towards a process of efficient and safe electric vehicle battery handling in the island Nordic countries

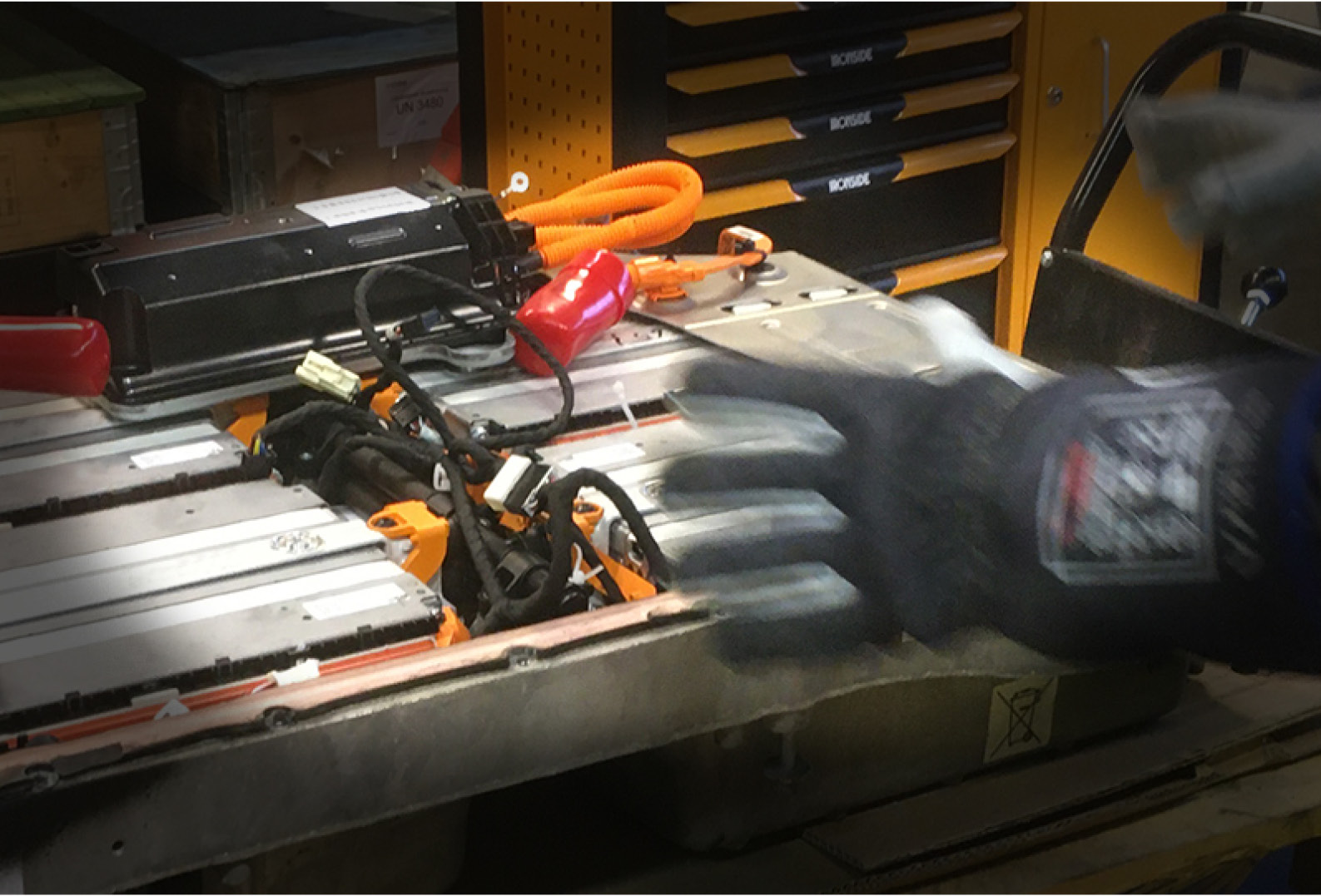

The number of electric vehicles (EVs) and hybrid electric vehicles (HEV) sold in the Nordic countries is quickly increasing, therefore there is a considerable need of designing a safe and efficient system to collect, transport, dismantle and recycle the batteries. One of the main energy sources used in EVs is lithium ion (Li-ion) battery. An important step for batteries destined for recycling is the pre-treatment process. During this process, the battery is discharged and dismantled into its constituent components. The pre-treatment process is mostly done manually today and may comprise considerable ergonomics and safety risks for the operators.

What do we do to meet the challenge

The aim of this project is to set up an efficient and safe process for end-of-life handling of Li-ion batteries used in vehicles in the Nordic countries, focusing on three islands: Iceland, the Faroe Islands, and Greenland. The volumes of end-of-life batteries are still low in these countries, but all of them have ambitious goals of increasing import of EVs. Therefore, there is a potential to develop a process/system for efficient end-of-life EV battery handling from the start and prepare for the upcoming volumes of batteries in the near future. The scope of this project will include collection, packaging, pre-treatment process of EV batteries, developing guidelines for that work, and training.

By the end of this project, the following short-term objectives will be achieved:

- Map the current status of processes related to EV battery handling in the Faroe Islands, Greenland, and Iceland

- Determine the needs of the three island countries based on the prerequisites in each one and do benchmark of the end-of-life battery handling process with the leading Nordic countries to fill in the gaps

- Establish a concept and prototype for battery collection based on the prerequisites of each participating country, including special packaging needs for complete good battery packs as well as damaged ones

- Develop a concept and protype of a pre-treatment process from receiving the batteries, through the required steps to discharge the battery, remove all the liquids, dismantle the battery pack down to the modules/cell levels, according to the safety and ergonomics principles

- Establish digital and physical training material and guidelines related to battery handling based on the best practice/lessons learned from the other Nordic countries

- The companies involved in the project will become physical demonstrators of the conceptualized systems and start testing the procedures, work according to the safety requirements including protective equipment, adapt ergonomics guidelines for the manual work (good working postures, tools to alleviate problems related to heavy weights, repetitive work, etc.).

The long-term objectives of this project are to enable a sustainable transition to an electrified transportation system by creating sustainable end-of-life treatment process for the batteries that are essential for the transition to take place, and to support building a strong battery pre-treatment industry within the island Nordic countries.

Project partners and financer

Stiftelsen Chalmers Industriteknik is the project leader and coordinator.

The recycling companies are: IRF and Kommunala Brennistøðin (The Faroe Islands), ESANI A/S (Greenland), Netpartar ehf. and Hringras ehf (Iceland). They will be responsible for the practical part, enabling testing, prototype, and demonstrator implementation.

Stena Recycling A/S and Stena Recycling International AB will contribute with lessons learned and support.

Destructor Consulting will support to develop an appropriate packaging for the batteries, as well as develop guidelines and training material for all operators about the safe battery handling.

The project is financed by Nordic Innovation.

Project period August 2020 – August 2022